Well, my T&S shoe box mold wasn't skinny enough. I was pretty sure it wasn't going to be, but then I thought, 'maybe I can cut the soap in half to get it to be skinny enough' but then it's too skinny. And if I cut it in half in the other direction, it would just defeat the purpose.

So I am again on the lookout for a substitute T&S mold (shoe box or something similar) to test out. But so far I haven't really found any design that jumps out at me to use with a T&S mold, so am not in that great a hurry. I'll just have to keep an eye out when shopping in future. Or re-visit my cardboard boxes upstairs. I think I have one around here that caught my eye as a possibility.

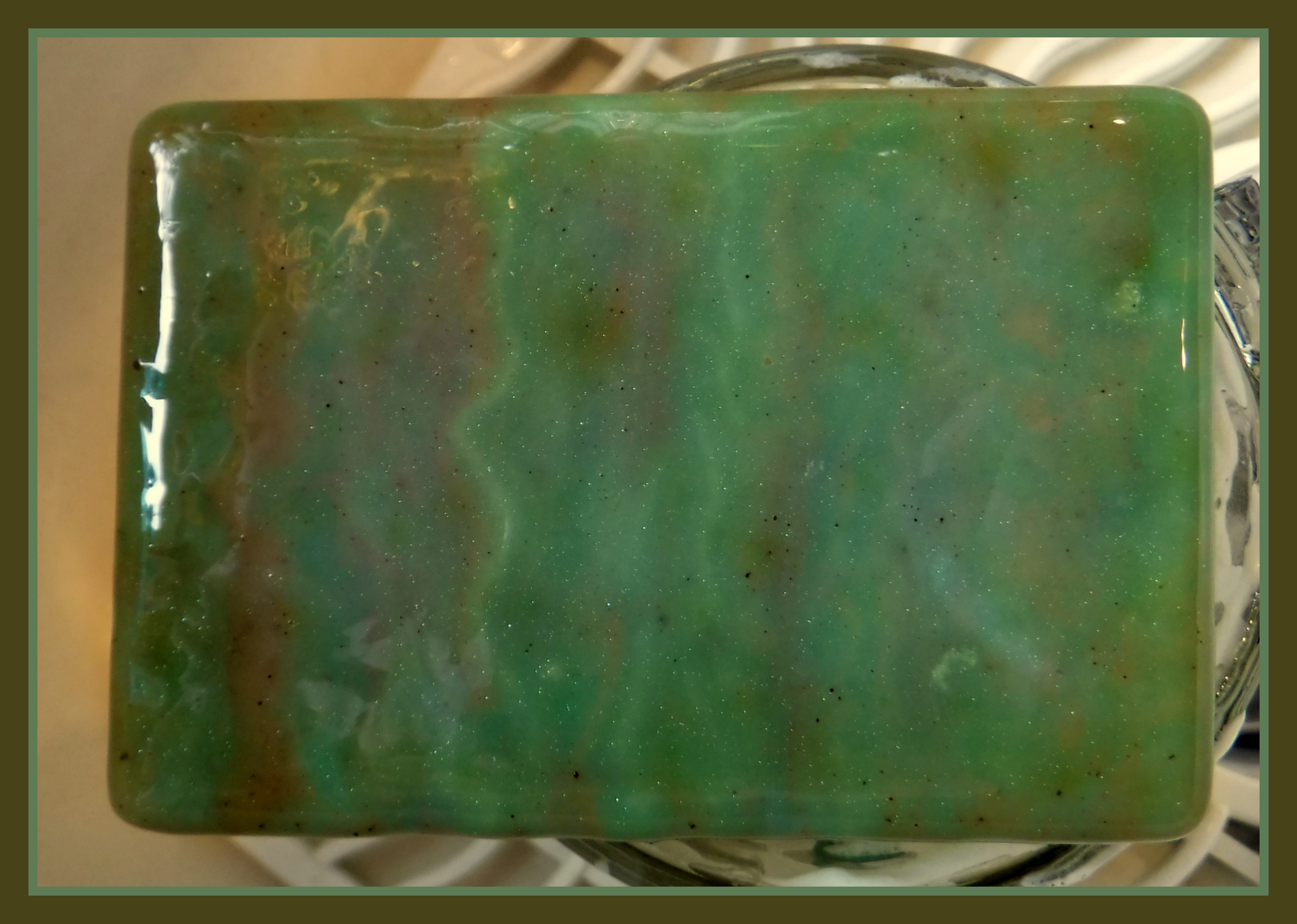

But the tall shoe box mold worked out pretty well for a crockpot full of rebatch. With the size of my crockpot I can fill this mold completely and not have to use two, so I may keep it around for a while for that purpose.

So I am again on the lookout for a substitute T&S mold (shoe box or something similar) to test out. But so far I haven't really found any design that jumps out at me to use with a T&S mold, so am not in that great a hurry. I'll just have to keep an eye out when shopping in future. Or re-visit my cardboard boxes upstairs. I think I have one around here that caught my eye as a possibility.

But the tall shoe box mold worked out pretty well for a crockpot full of rebatch. With the size of my crockpot I can fill this mold completely and not have to use two, so I may keep it around for a while for that purpose.