Cheese

Member

Hello, glad to find this forum!

I am new to soap making. In keeping with my traditional living, I want to make soap the old way. We do a lot of things around my place the old way to keep it alive. We cure country hams that don't need refrigeration, bacon, have a blacksmith shop, make wine, make syrup, and lots of other things like that. In the process of growing and processing our pigs, we get a lot of lard sometimes and a lot of hardwood ashes from running the smokehouse. So... the next step is pretty well laid out for us... soap!

I built a leaching trough to leach rainwater through the ashes and collected a good bit, then I simmered it down until it floats an egg. Then I used the measurements of 1 cup of lard to 3/8 cup of lye solution. On the first attempt, we stirred for hours and it never thickened at all. I added more lye and nothing, then more, and still nothing. Finally we cooked it down on the stove for a few hours and gave up on it. The next day, we have what looks like beige butter in the pot. It's still soft though, it can't be handled and when I test it to see if it acts as soap, it is greasy and has to be washed off with real soap. Will that change as it "cures"?

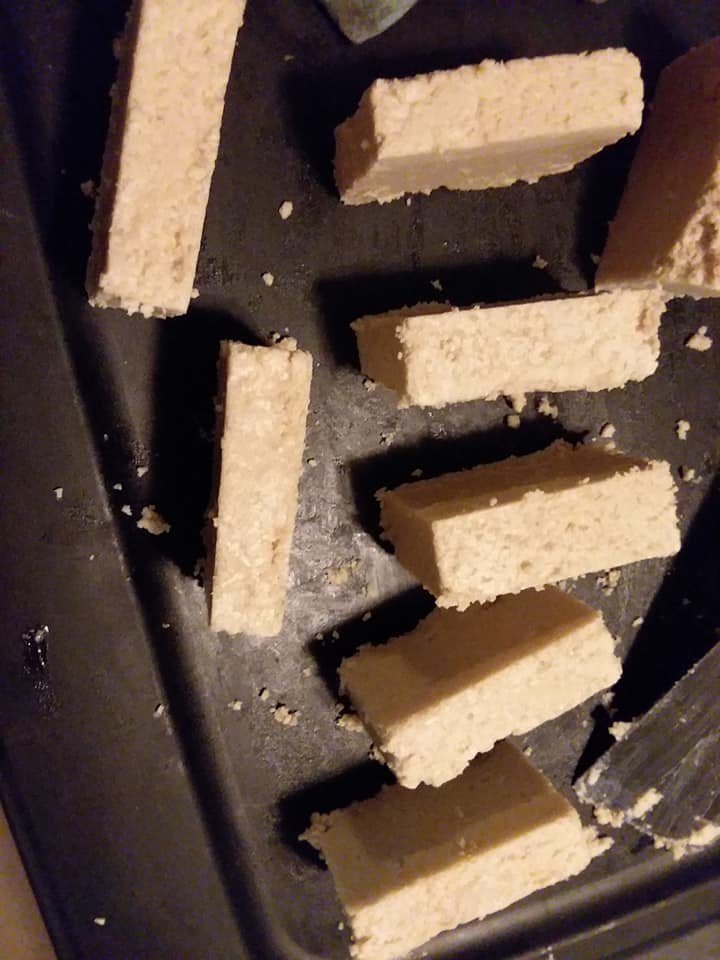

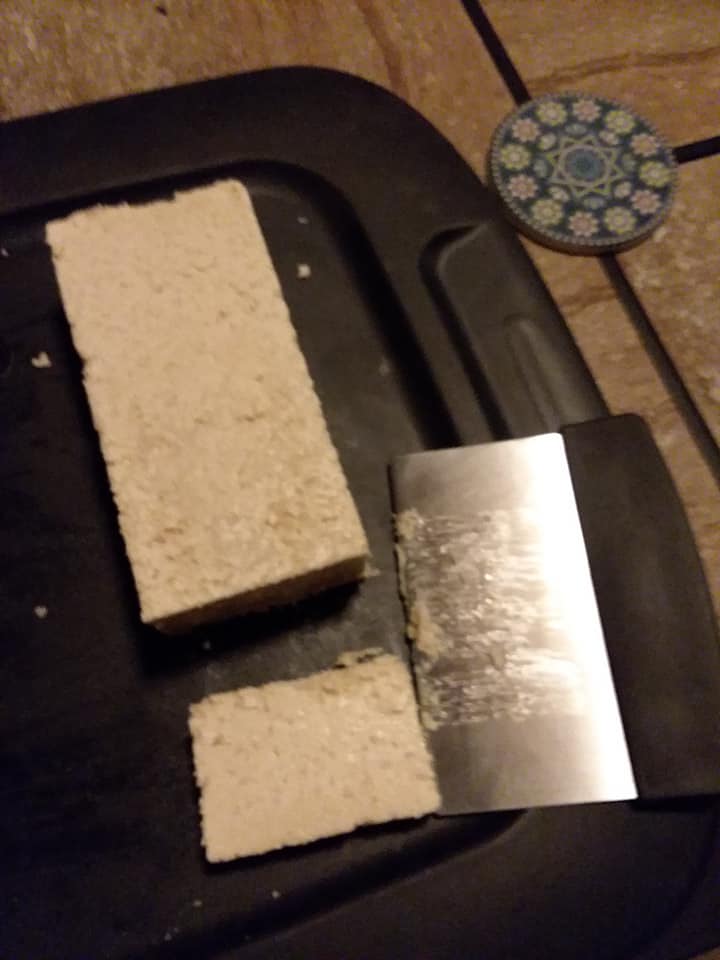

While that batch was being simmered down and basically given up on, we tried another batch using tallow instead of lard. It did thicken up to a trace as expected and we poured it into a mold. It's been 24 hours and that is still too soft to handle. When I test it, it's also greasy under water and has to be washed off with real soap.

Did we fail at making soap, or is it supposed to be that way until it cures? Any suggestions or input is greatly appreciated!

I am new to soap making. In keeping with my traditional living, I want to make soap the old way. We do a lot of things around my place the old way to keep it alive. We cure country hams that don't need refrigeration, bacon, have a blacksmith shop, make wine, make syrup, and lots of other things like that. In the process of growing and processing our pigs, we get a lot of lard sometimes and a lot of hardwood ashes from running the smokehouse. So... the next step is pretty well laid out for us... soap!

I built a leaching trough to leach rainwater through the ashes and collected a good bit, then I simmered it down until it floats an egg. Then I used the measurements of 1 cup of lard to 3/8 cup of lye solution. On the first attempt, we stirred for hours and it never thickened at all. I added more lye and nothing, then more, and still nothing. Finally we cooked it down on the stove for a few hours and gave up on it. The next day, we have what looks like beige butter in the pot. It's still soft though, it can't be handled and when I test it to see if it acts as soap, it is greasy and has to be washed off with real soap. Will that change as it "cures"?

While that batch was being simmered down and basically given up on, we tried another batch using tallow instead of lard. It did thicken up to a trace as expected and we poured it into a mold. It's been 24 hours and that is still too soft to handle. When I test it, it's also greasy under water and has to be washed off with real soap.

Did we fail at making soap, or is it supposed to be that way until it cures? Any suggestions or input is greatly appreciated!