Jean

Well-Known Member

- Joined

- Feb 18, 2008

- Messages

- 85

- Reaction score

- 0

I don't know if you would call this a salt bar or not, but I was wanting to run the recipe past you to see if it sounds okay. I sort of made it up, using what I had on hand.

This is a RTCP Soap made on July 19

23 % Soybean Oil (liquid Vegetable Oil in a jug)

Coconut Oil 38% (76 Deg. solid)

35% Armour Lard

Castor Oil 4 % ( shorted this by l.04 gms. because that was all I had)

3 tsp. sea salt

3 tsp sugar syrup

pinch of silk

Lye 7.09 oz.

Water 18.24 oz.

Mica and Cedarwood FO

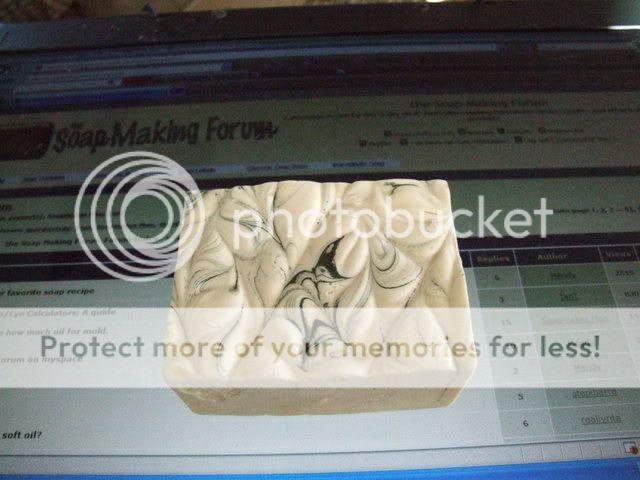

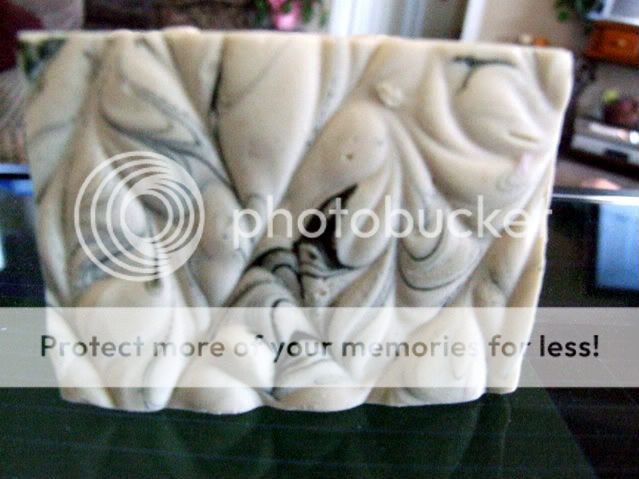

Poured and did swirling at light trace and had plenty of time to do so.

I unmolded after about 36 hours. It seems to be a tad bit "gummy" when I tried to bevel the bars. I think it is going to be okay after a bit more curing time. I am just wondering if I am going to have a very good bar of soap. I just put the salt in to try something different, don't know what the benefits are. I can post a pic. if anyone is interested in seeing it.

Jean

This is a RTCP Soap made on July 19

23 % Soybean Oil (liquid Vegetable Oil in a jug)

Coconut Oil 38% (76 Deg. solid)

35% Armour Lard

Castor Oil 4 % ( shorted this by l.04 gms. because that was all I had)

3 tsp. sea salt

3 tsp sugar syrup

pinch of silk

Lye 7.09 oz.

Water 18.24 oz.

Mica and Cedarwood FO

Poured and did swirling at light trace and had plenty of time to do so.

I unmolded after about 36 hours. It seems to be a tad bit "gummy" when I tried to bevel the bars. I think it is going to be okay after a bit more curing time. I am just wondering if I am going to have a very good bar of soap. I just put the salt in to try something different, don't know what the benefits are. I can post a pic. if anyone is interested in seeing it.

Jean