Hello everyone I've recently discovered soaping and it seems like a very cool hobby. I've been doing a lot of reading for the past week and watched plenty of YouTube videos. I'm somewhat confident about making my first batch of soap but do have some questions for you all. I will be making cold process soap with olive oil cocoa butter and coconut oil.

I'm going to be buying all the ingredients and loaf mould stick blender etc monday when I get paid. so hopefully ill be making my first batch next week sometime.

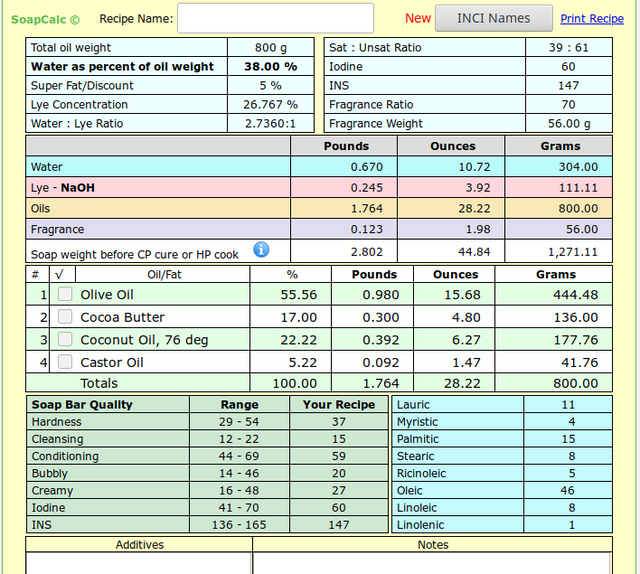

I have been playing around with soap calc and seem to have a pretty good grasp of it now but it did take a few tries. It's surprisingly simple once you get your head around it.

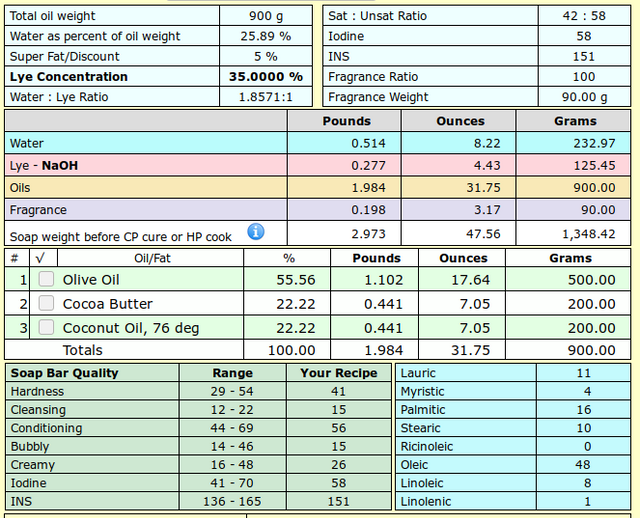

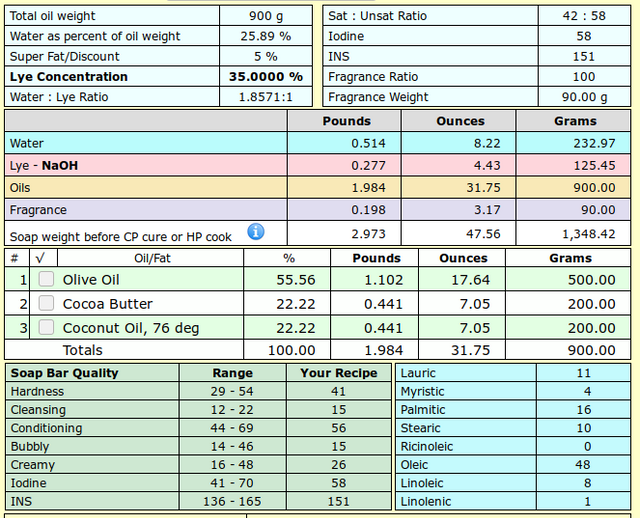

I have decided for no particular reason to make a recipe with 500g olive oil 200g coconut oil and 200g of cocoa butter.

I'm going to be using lemon fragrance oil and the fragrance is recommended to be added at a 10% ratio. so does 90g of fragrance oil seem ok for this batch size?

Is my Lye concentration ok in the above recipe? Should I go less or more ?

I will also be using lemon yellow mica powder to give the soap some colour

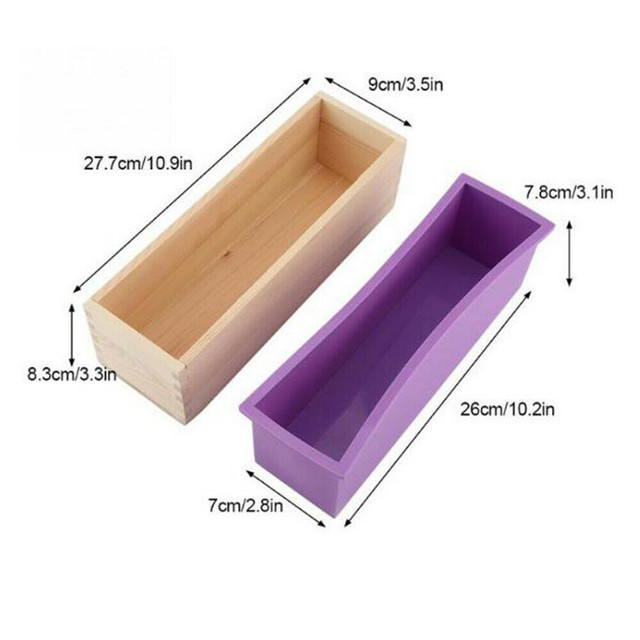

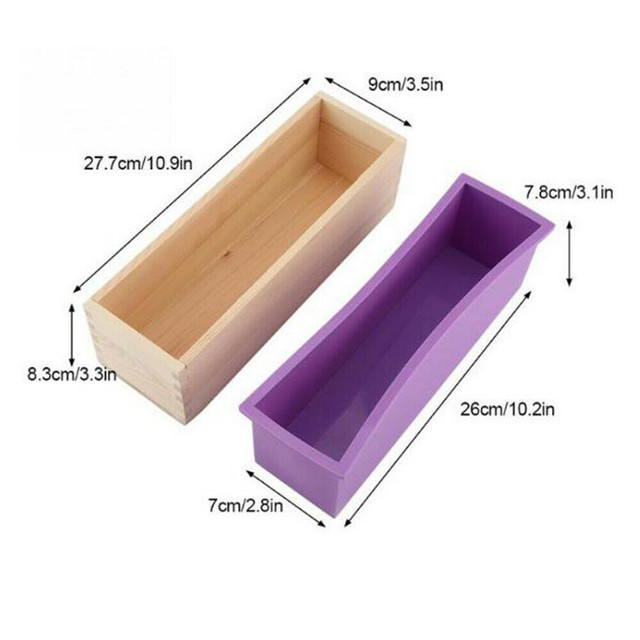

This is the mould I will be using-

I take it the above recipe will be more than enough for this mould? I don't mind if I have a little bit left over but I don't want to make way to much either so let me know if I need to adjust the recipe.

Also I could make the recipe with just olive oil and cocoa butter and maybe ditch the coconut oil ? I'm not really fussed

Thanks in advance!

I'm going to be buying all the ingredients and loaf mould stick blender etc monday when I get paid. so hopefully ill be making my first batch next week sometime.

I have been playing around with soap calc and seem to have a pretty good grasp of it now but it did take a few tries. It's surprisingly simple once you get your head around it.

I have decided for no particular reason to make a recipe with 500g olive oil 200g coconut oil and 200g of cocoa butter.

I'm going to be using lemon fragrance oil and the fragrance is recommended to be added at a 10% ratio. so does 90g of fragrance oil seem ok for this batch size?

Is my Lye concentration ok in the above recipe? Should I go less or more ?

I will also be using lemon yellow mica powder to give the soap some colour

This is the mould I will be using-

I take it the above recipe will be more than enough for this mould? I don't mind if I have a little bit left over but I don't want to make way to much either so let me know if I need to adjust the recipe.

Also I could make the recipe with just olive oil and cocoa butter and maybe ditch the coconut oil ? I'm not really fussed

Thanks in advance!