I have searched what seems like an endless amount of threads that mention "silicone" but have been unable to find what I'm looking for. I made a wood slab mold and purchased the silicone liner that fits it from Brambleberry. I love that the soap is easy to unmold and that I don't have to use freezer paper, but the silicone causes bubbles on the sides and bottom of my soap slab. I poured and insulated with blankets the first time, the second I tried the cpop process ( which only made everything worse because it added bubbles go the top of the slab). I see and hear a lot of people liking the silicone molds, so why am I getting bubbles? I have gone to lining the wood with paper, which has its own challenges. I suppose I need to try the freezer method to complete the trifecta, and prevent the soap from hitting gel, but I can't imagine that this is the only answer. Thank you.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

silicone liner causes bubbles

- Thread starter Cemetery

- Start date

Help Support Soapmaking Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

ocean_soul

Well-Known Member

I remember reading this interesting tidbit regarding CPOP and silicone molds on the Soap Queen blog:

"While technically, you can use silicone that’s rated for baking, like the rad Bramble Berry liners and awesome silicone loaf mold, there’s an interesting thing that happens with silicone and a super hot gel phase. The soap sort of ‘boils’ on the inside and something about the lack of breathing in silicone makes little air bubble/water bubble pock marks on the entire outside of the loaf. It is more than frustrating to go through the extra work of CPOP, only to find your soap loaf pitted and pocked. The freezer paper gives it breathability that silicone liners or molds don’t give you."

Maybe next time you use your silicone liner you should insulate it less, that way it doesn't heat up as much.

"While technically, you can use silicone that’s rated for baking, like the rad Bramble Berry liners and awesome silicone loaf mold, there’s an interesting thing that happens with silicone and a super hot gel phase. The soap sort of ‘boils’ on the inside and something about the lack of breathing in silicone makes little air bubble/water bubble pock marks on the entire outside of the loaf. It is more than frustrating to go through the extra work of CPOP, only to find your soap loaf pitted and pocked. The freezer paper gives it breathability that silicone liners or molds don’t give you."

Maybe next time you use your silicone liner you should insulate it less, that way it doesn't heat up as much.

ocean_soul

Well-Known Member

Hmm, I don't have a wood mold with a silicone liner but I do have a silicone loaf mold that I use. What I do is insulate it fairly well then I check on it periodically, taking its temp each time. If I think it's getting to warm then I remove some or all of my insulation. I imagine that with a wood mold you shouldn't need too much insulation.

seife1441

Member

I use silikon molds all the time and I know what you mean about the bubbles...I call it "Heat Pitting". I usually get it in my smaller form molds and have adjusted the insulation to take this into consideration.

For my larger molds...5Kg and such. I attached Food grade silikon Sheets to Wood to make the demoulding easier. I do not have a Problem with heat pitting in the larger molds.

There should be no Problem with letting your Soap go into the gel Phase. All mine does and it Comes out fine. However, certain oil mixtures will heat pit easier than others. You can also adjust your mixture a bit and try to find one that is compatable with your production parameters

For my larger molds...5Kg and such. I attached Food grade silikon Sheets to Wood to make the demoulding easier. I do not have a Problem with heat pitting in the larger molds.

There should be no Problem with letting your Soap go into the gel Phase. All mine does and it Comes out fine. However, certain oil mixtures will heat pit easier than others. You can also adjust your mixture a bit and try to find one that is compatable with your production parameters

seife1441

Member

Hi Cemetery,

Here is a for instance about bubbles forming in Silikon forms:

Yesterday I tried a new essential oil...lime oil. The first form I tried it on is my quadratic form...I made the form out of silikon rubber. The Lime oil behaved well as far as not causing a run away reaction like some essential oils (beware of Thyme oil:think

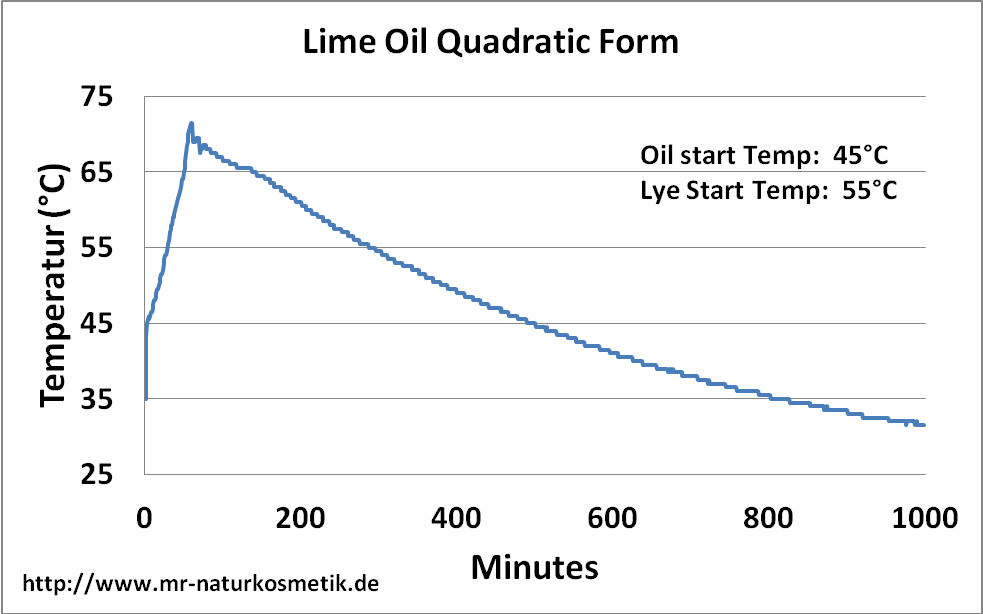

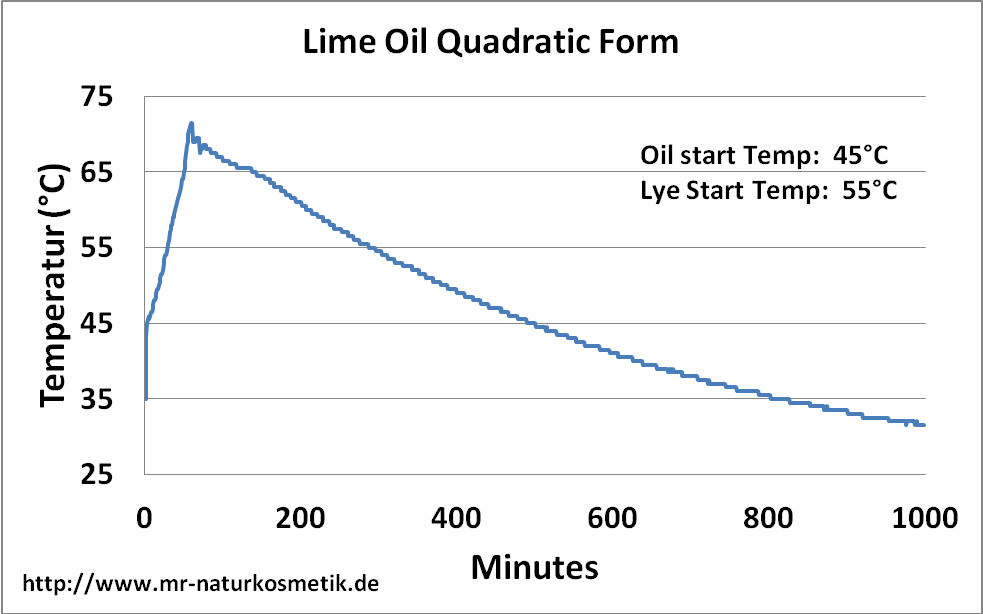

For the first time using this essential oil, I put a thermocouple attached to a data logger between the plastic sheet covering the Soap in the form and the insulation. This will measure the temperature of the Soap as the reaction proceeds.

Below is the temperature vs. time curve during the reaction.

The reaction reached a Maximum temperature of 71.5°C at 51 minutes into the process. That is on the high side and heat pitting can be expected.

However when the samples were removed, typical heat pitting marks were not seen. The bubbles on the back of the sample are air bubbles that were caught between the Soap and the plastic sheet.

The bars demolded very well. The fronts do have some of what appear to be heat pits but they are not grouped the way they usually are.

The next time I will lower the starting temperature and this usually will also lower the Maximum temperature reached during the reaction.

From the results, it appears that lime oil is a well behaved essential oil and will be one of the easier ones to work with as far as producing moulded form Soaps.

The bar smells really nice too. I Just started a new bar in the bathroom but I think I just might use this one for my morning shower tomorrow.

Here is a for instance about bubbles forming in Silikon forms:

Yesterday I tried a new essential oil...lime oil. The first form I tried it on is my quadratic form...I made the form out of silikon rubber. The Lime oil behaved well as far as not causing a run away reaction like some essential oils (beware of Thyme oil:think

For the first time using this essential oil, I put a thermocouple attached to a data logger between the plastic sheet covering the Soap in the form and the insulation. This will measure the temperature of the Soap as the reaction proceeds.

Below is the temperature vs. time curve during the reaction.

The reaction reached a Maximum temperature of 71.5°C at 51 minutes into the process. That is on the high side and heat pitting can be expected.

However when the samples were removed, typical heat pitting marks were not seen. The bubbles on the back of the sample are air bubbles that were caught between the Soap and the plastic sheet.

The bars demolded very well. The fronts do have some of what appear to be heat pits but they are not grouped the way they usually are.

The next time I will lower the starting temperature and this usually will also lower the Maximum temperature reached during the reaction.

From the results, it appears that lime oil is a well behaved essential oil and will be one of the easier ones to work with as far as producing moulded form Soaps.

The bar smells really nice too. I Just started a new bar in the bathroom but I think I just might use this one for my morning shower tomorrow.

Last edited:

Very interesting! What mixture of oils have you've found to cause heat pitting for you? As a general practice I avoid gell but this weekend made a small batch in a silicone mold that I gelled with no heat pits. It could be the mixture of oils, or high/excessive temperatures, or even a silicone lined wood mold (not just silcone) that may have a tendency to cause them. It would be interesting to hear what others have experienced.

BTW - nice soap! Love the color.

BTW - nice soap! Love the color.

Seife, thank you for the detailed response. I am using a silicone lined wood mold and insulating. Unfortunately the silicone liner is not rigid enough to use without the frame. Perhaps I will try the same soap mixture and temperatures with a more rigid silicone mold and see the results.

The heat bubbles I was getting are very obvious and cover the entire bottom of the soap, not few and far between like you have pictured. Thank you.

The heat bubbles I was getting are very obvious and cover the entire bottom of the soap, not few and far between like you have pictured. Thank you.

seife1441

Member

Cemetery, I use silikon lined wooden mold for my "Cut" Soap. I got 1mm thick silikon sheet (Food Grade) and attached it to laminated particle board. I just cover it with a towel and I do not have a Problem there with heat pitting. How much insulation are you putting around your form?

The same day I did the lime in the Picture above I also did some apple blossom rose forms. I have not done them in awhile and was nto sure if I had notes on it. The first run came out heat pitted. I did it over again last night but I lowered the starting temperature and left the bottom of the supporting insulation open to the air to Keep the temperature in the problem area lower. The result was only on rose had heat pits that were of acceptable quantity.

If you are getting the heat pits on the bottom of your form then try a configuration that keeps the bottom cooler...like Setting the form up on blocks to let air under it.

The same day I did the lime in the Picture above I also did some apple blossom rose forms. I have not done them in awhile and was nto sure if I had notes on it. The first run came out heat pitted. I did it over again last night but I lowered the starting temperature and left the bottom of the supporting insulation open to the air to Keep the temperature in the problem area lower. The result was only on rose had heat pits that were of acceptable quantity.

If you are getting the heat pits on the bottom of your form then try a configuration that keeps the bottom cooler...like Setting the form up on blocks to let air under it.

Similar threads

- Replies

- 73

- Views

- 4K

- Replies

- 4

- Views

- 892