nighttrain123

Member

I made two recipes: A and B.

A was:

Olive oil Pomace 454 g

Coconut oil 284 g

Palm oil 170 g

Water 312 g

Lye 130 g

This is water: lye of 2.4:1 and superfatted at 5% and 29.4% lye.

B was:

Olive oil Pomace 227 g

Coconut oil 227 g

Palm oil 170 g

Castor oil 170 g

Almond oil, sweet 113 g

Water 305 g

Lye 127 g

This is water: lye of 2.4:1 and superfatted at 5% and 29.4% lye.

Both were wrapped in a tea towel and had a cardboard lid. I left them for 24 hrs in a room at about 20 deg C.

I mixed the lye in the fats/oils when both were about 120 deg F. B reached trace quite fast and got quite thick taking me a bit by surprise. It's possible it wasn't perfectly mixed 'cos of this. It was hard to smooth the top of the loaf 'cos it was so thick, and it all got a bit messy on the sides as you can see.

As I understand this both soaps have cracked a bit (A is worst) 'cos they got too hot. I'm thinking that next time I should not use the tea towel and cardboard lid? This should result in a smoother top?

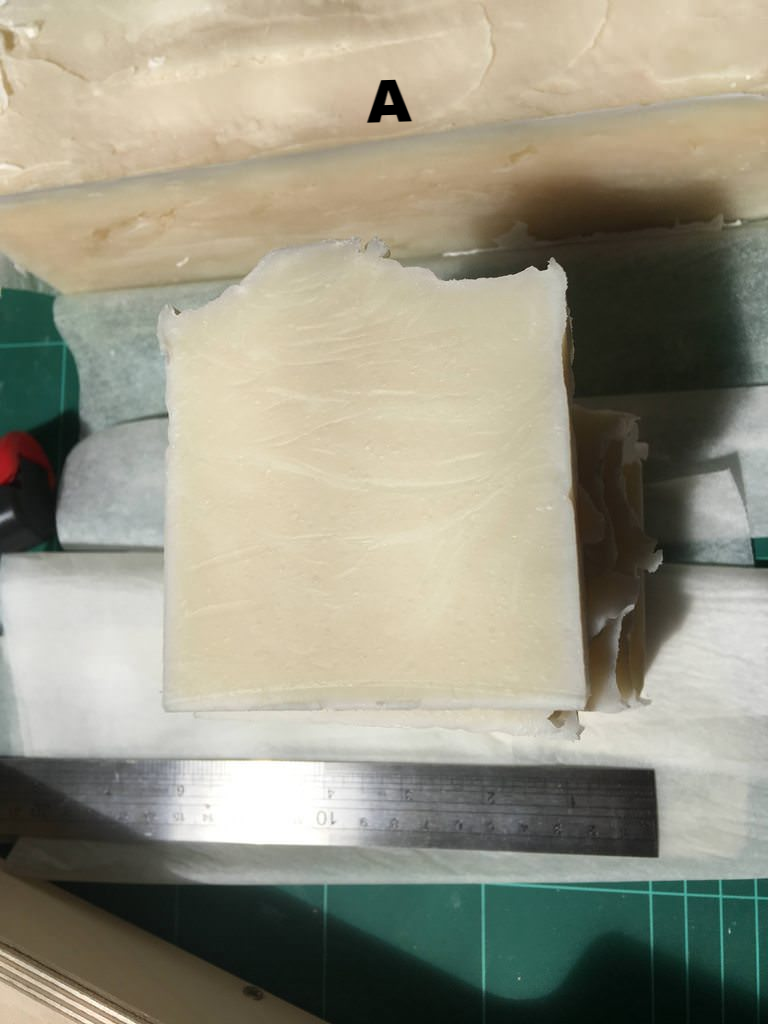

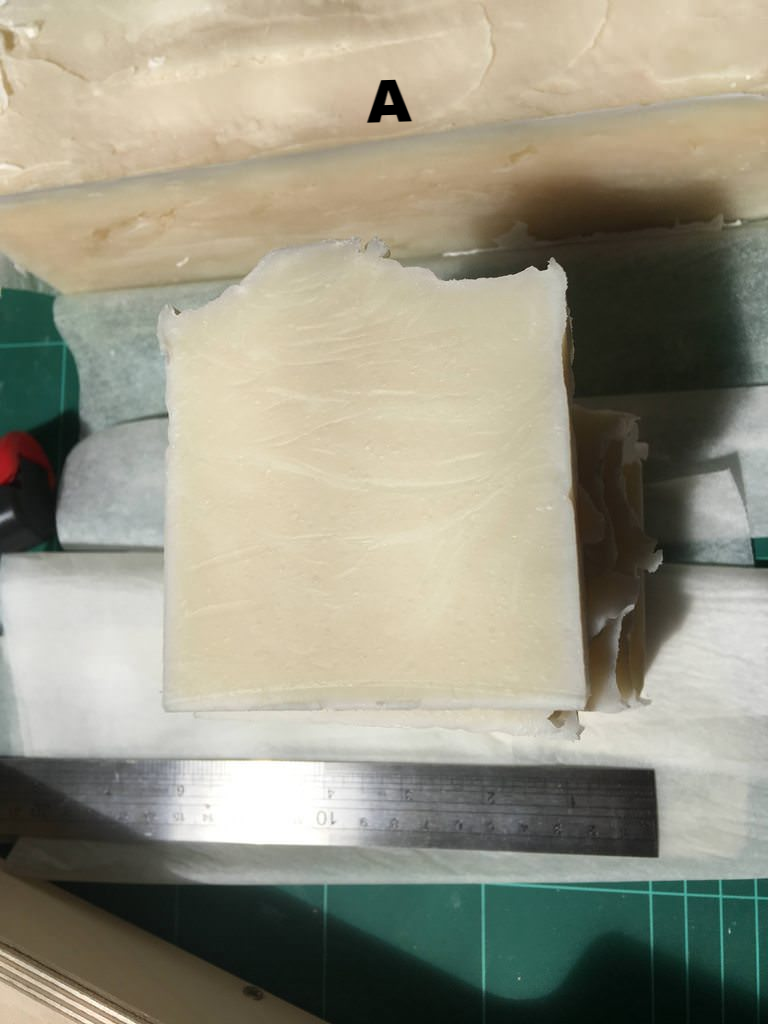

Cross section through the middle of A shows it's fairly homogeneous and I think it tells me that it gelled completely? Apart from getting too hot and cracking/messing up the top this seems fairly successful?

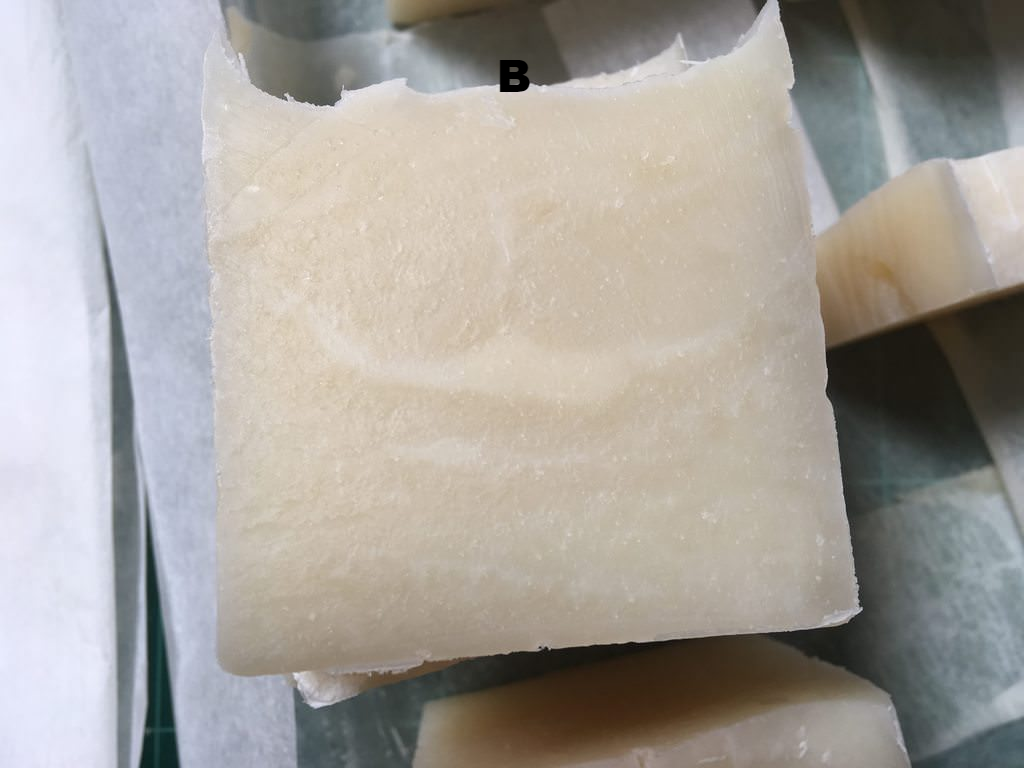

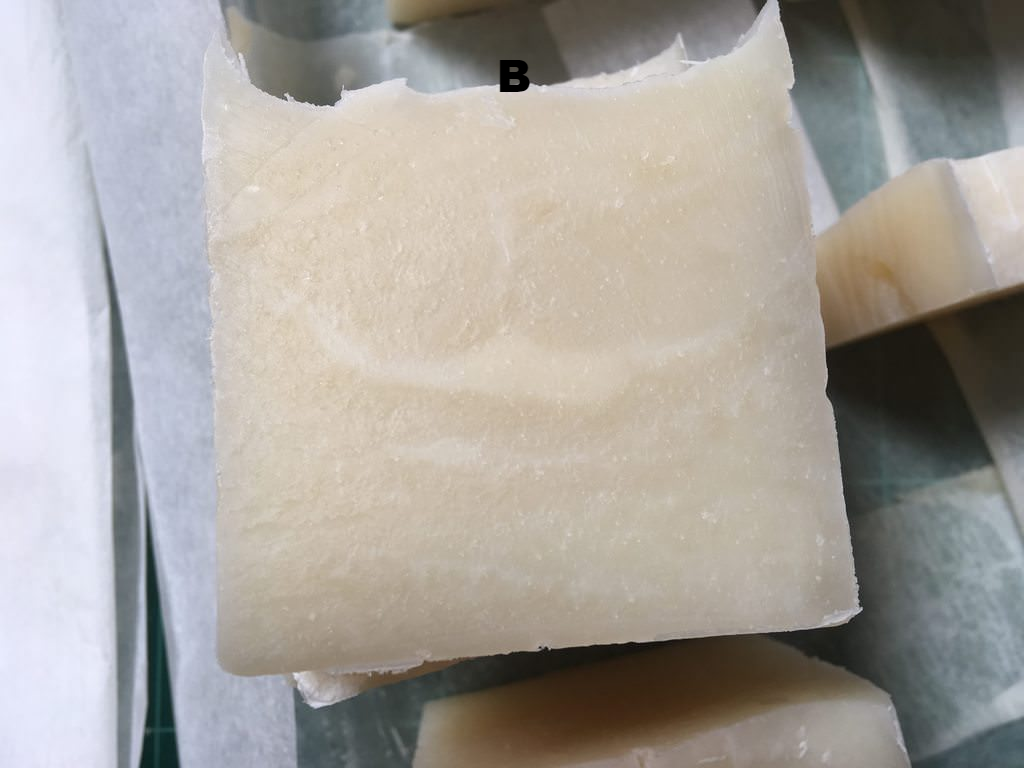

B isn't quite as good. Apart from the heterogeneity here, I can see that the outside of the loaf 'sweated' a bit. This is glycerin I think and tells me I need to cut down on the water? I think the whole loaf has gelled and the heterogeneity I see is the result of poor mixing, but I'm not 100% sure.

So I'm concluding that I need to dispense with insulation and think about reducing the water especially for B.

This leads me to think that it would be easiest to just put the loaf in my fridge and have it not gel as well? Seems easy way to control the temp? Consistent smooth top? My room temp is gonna change with the weather.

Also I think maybe 120 deg F is a bit high to mix so I should reduce this down to 80 deg to 100 deg F next time.

A was:

Olive oil Pomace 454 g

Coconut oil 284 g

Palm oil 170 g

Water 312 g

Lye 130 g

This is water: lye of 2.4:1 and superfatted at 5% and 29.4% lye.

B was:

Olive oil Pomace 227 g

Coconut oil 227 g

Palm oil 170 g

Castor oil 170 g

Almond oil, sweet 113 g

Water 305 g

Lye 127 g

This is water: lye of 2.4:1 and superfatted at 5% and 29.4% lye.

Both were wrapped in a tea towel and had a cardboard lid. I left them for 24 hrs in a room at about 20 deg C.

I mixed the lye in the fats/oils when both were about 120 deg F. B reached trace quite fast and got quite thick taking me a bit by surprise. It's possible it wasn't perfectly mixed 'cos of this. It was hard to smooth the top of the loaf 'cos it was so thick, and it all got a bit messy on the sides as you can see.

As I understand this both soaps have cracked a bit (A is worst) 'cos they got too hot. I'm thinking that next time I should not use the tea towel and cardboard lid? This should result in a smoother top?

Cross section through the middle of A shows it's fairly homogeneous and I think it tells me that it gelled completely? Apart from getting too hot and cracking/messing up the top this seems fairly successful?

B isn't quite as good. Apart from the heterogeneity here, I can see that the outside of the loaf 'sweated' a bit. This is glycerin I think and tells me I need to cut down on the water? I think the whole loaf has gelled and the heterogeneity I see is the result of poor mixing, but I'm not 100% sure.

So I'm concluding that I need to dispense with insulation and think about reducing the water especially for B.

This leads me to think that it would be easiest to just put the loaf in my fridge and have it not gel as well? Seems easy way to control the temp? Consistent smooth top? My room temp is gonna change with the weather.

Also I think maybe 120 deg F is a bit high to mix so I should reduce this down to 80 deg to 100 deg F next time.