The kids are asleep, and I pulled out the plan and supplies. Though at first glance the recipe might appear simple or foolish, it is not some lark, nor a random thought, but a result of many hours snatched away from less productive and less fun things (mostly work, sleep...and cooking) reading into the depths of SMF, a few shave forums, and going through some dozens of iterations on SMFriend calc to see exactly how far I can take the famous RBO.

The goal of this soap:

To build a premium feeling soap with simple ingredients and without premium or "luxury" fats and oils. Emphasis on glide, skin feel, protection and explosive lather being a secondary concern. Working within the limits of 50% SA and seeing how far I can stretch other variables. The goal of a vegan and palm free shave soap (still working on glycerin...) is what started me down this road, and is also included in the challenge.

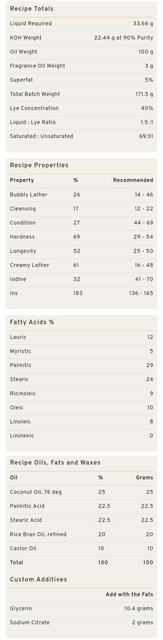

If you're shielding your eyes out of pity, don't worry, it's not actually this garishly colored in real life, the recipe:

The breakdown:

Hard fats=49% very close to the 50% guideline suggested by the very wise @ResolvableOwl

Stearic acid+Palmitic acid=50% RBO has the wonderful fatty acid profile, and is the one soft oil I can pump up this high and get away with having both the benefits of liquid oil and the shave benefit of palmitic acid. I lowered my commercial SA and raised RBO as much as I could without sacrificing 50 SA/PA.

PUFAs=a very worrying 32% -Edit, thanks RO-PUFAS actually 16 and just at the edge of dangerous instead of in the danger zone. I have included citric acid as a chelator on one of these tubs to compare both lather and DOS tendency. I'm aware CA is not ideal on it's own however. ROE is on the way, and I wish I could have included this in the experiment, it was not fated to be included. :-( This is a performance test more than anything.

Glycerin= 9.68 grams. Not a random number, I pulled this from @DeeAnna 's guideline of roughly 12% glycerine to replace the glycerine missing from commercial stearic acid. I added 5 percent to the TOW on top of that. I was unsure how much to add to get slip and hope this is not excessive or deficient.

Castor oil+coconut oil=20% I was very tempted to eliminate coconut oil completely due to its cleansing/stripping qualities. I even had a recipe lined up and ready to test before scrapping that idea. The fact is that Coconut is very useful being that it "breaks" down very easily. Despite castor being an awesome bubble enhancer I'm not sure of its suitability in shave lather considering RO's latest experiments with liquid soap and very loud crackling. I will explore that later. This recipe eventually ended up as an SA+RBO+10% castor oil with coconut wedging it's way back in.

RBO=magical wonder oil? Maybe, I'll find out in 2 weeks.

Making this stuff: @The Efficacious Gentleman has shared his method of making microbatches in the microwave with small containers. This proved very doable and even less cleanup was required. In response to learning this method I scaled down my experiment batches from 150 g to 100 g and went out and purchased 12 oz #5PP plastic deli containers. These are perfectly sized for batch experimenting shave soaps as they are wide enough to build a lather with the final product, tall enough to stir hot oil and lye without spilling and still fairly compact. I preheated a small Pyrex baking dish with a small water bath before placing the tubs in to aid heating, and to hopefully keep the tubs warm when removed from the nuker. Worked great. No stick blending, which is unfortunate as I have been dying to use my new mini stick blender.

I want to thank EFG, RO, DeeAnna, @Professor Bernardo, @Zany_in_CO , @IrishLass for some very specific advice and sharing so much knowledge. I'm sure I've forgotten quite a few others. There are countless others to thank including some long lost trail blazers and prolific shave soapers, LBussy, songwind, Lindy, psfred to name a few.

The goal of this soap:

To build a premium feeling soap with simple ingredients and without premium or "luxury" fats and oils. Emphasis on glide, skin feel, protection and explosive lather being a secondary concern. Working within the limits of 50% SA and seeing how far I can stretch other variables. The goal of a vegan and palm free shave soap (still working on glycerin...) is what started me down this road, and is also included in the challenge.

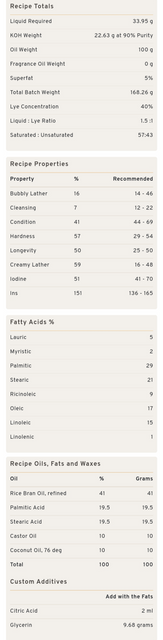

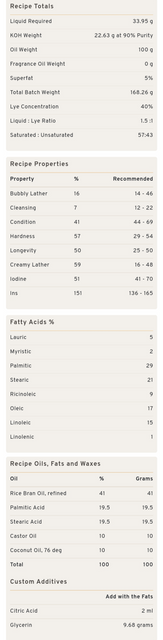

If you're shielding your eyes out of pity, don't worry, it's not actually this garishly colored in real life, the recipe:

The breakdown:

Hard fats=49% very close to the 50% guideline suggested by the very wise @ResolvableOwl

Stearic acid+Palmitic acid=50% RBO has the wonderful fatty acid profile, and is the one soft oil I can pump up this high and get away with having both the benefits of liquid oil and the shave benefit of palmitic acid. I lowered my commercial SA and raised RBO as much as I could without sacrificing 50 SA/PA.

PUFAs=

Glycerin= 9.68 grams. Not a random number, I pulled this from @DeeAnna 's guideline of roughly 12% glycerine to replace the glycerine missing from commercial stearic acid. I added 5 percent to the TOW on top of that. I was unsure how much to add to get slip and hope this is not excessive or deficient.

Castor oil+coconut oil=20% I was very tempted to eliminate coconut oil completely due to its cleansing/stripping qualities. I even had a recipe lined up and ready to test before scrapping that idea. The fact is that Coconut is very useful being that it "breaks" down very easily. Despite castor being an awesome bubble enhancer I'm not sure of its suitability in shave lather considering RO's latest experiments with liquid soap and very loud crackling. I will explore that later. This recipe eventually ended up as an SA+RBO+10% castor oil with coconut wedging it's way back in.

RBO=magical wonder oil? Maybe, I'll find out in 2 weeks.

Making this stuff: @The Efficacious Gentleman has shared his method of making microbatches in the microwave with small containers. This proved very doable and even less cleanup was required. In response to learning this method I scaled down my experiment batches from 150 g to 100 g and went out and purchased 12 oz #5PP plastic deli containers. These are perfectly sized for batch experimenting shave soaps as they are wide enough to build a lather with the final product, tall enough to stir hot oil and lye without spilling and still fairly compact. I preheated a small Pyrex baking dish with a small water bath before placing the tubs in to aid heating, and to hopefully keep the tubs warm when removed from the nuker. Worked great. No stick blending, which is unfortunate as I have been dying to use my new mini stick blender.

I want to thank EFG, RO, DeeAnna, @Professor Bernardo, @Zany_in_CO , @IrishLass for some very specific advice and sharing so much knowledge. I'm sure I've forgotten quite a few others. There are countless others to thank including some long lost trail blazers and prolific shave soapers, LBussy, songwind, Lindy, psfred to name a few.

Last edited: