Techie Joe

Well-Known Member

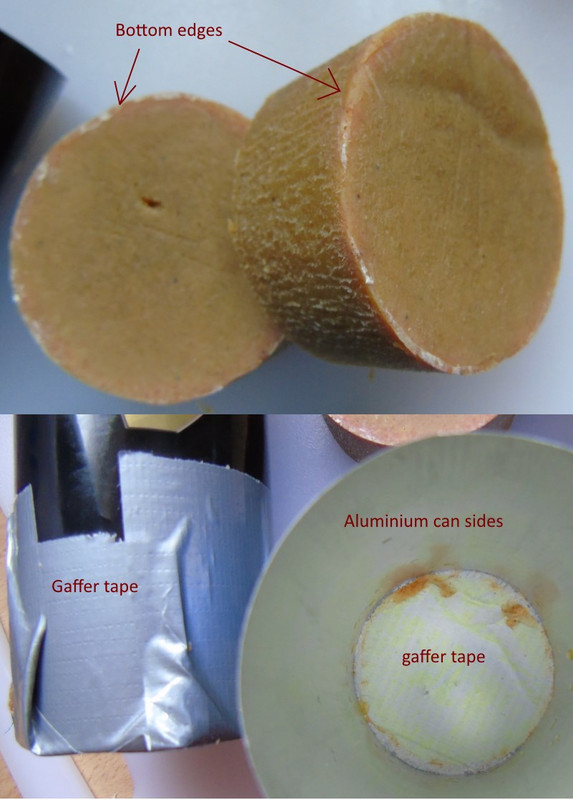

Made this two days ago, first time making cold process.

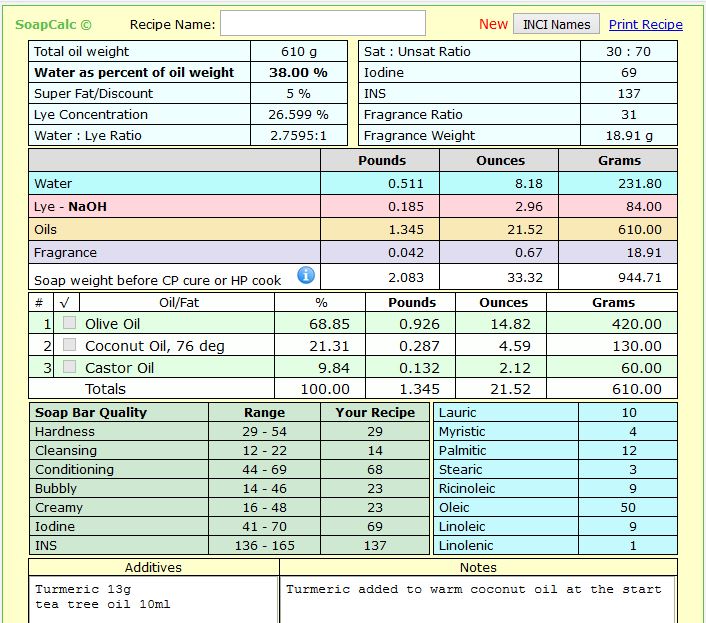

Its still tacky and quite dark in the middle, there is a lot of Olive oil in it, smells nice.

I started by warming up the jar of coconut oil in a low oven, and making the caustic soda solution

I put the coconut oil in a 1 liter measuring jug and added about 13 grams of turmeric, then blended

I added the Olive and Castor oils and blended again

I added the soda and blended on and off until medium trace

I added 10 ml of Tea Tree oil and blended until mixed

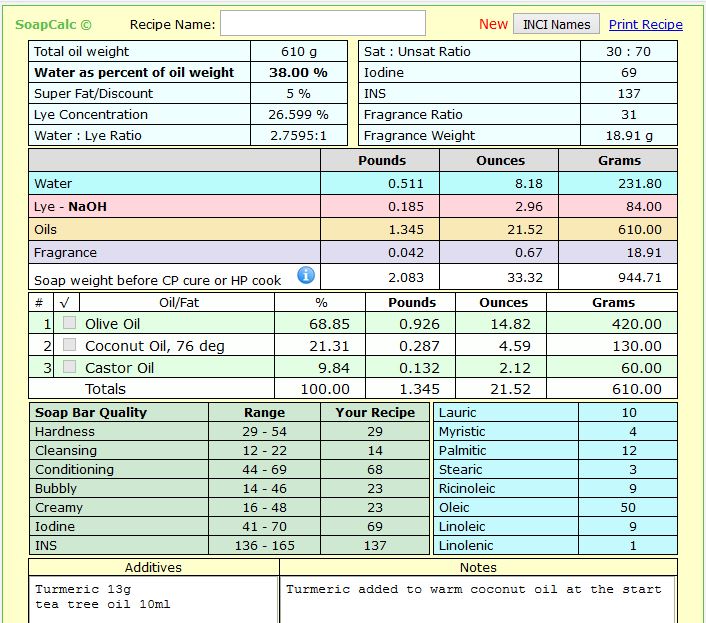

Then I poured the mixture into two beer can moulds and covered in cling film

Does anyone know why the center of the soap is dark?

Are other people's cold process soaps still tacky after 2 days?

Thanks

Constructive comments welcome.

Its still tacky and quite dark in the middle, there is a lot of Olive oil in it, smells nice.

I started by warming up the jar of coconut oil in a low oven, and making the caustic soda solution

I put the coconut oil in a 1 liter measuring jug and added about 13 grams of turmeric, then blended

I added the Olive and Castor oils and blended again

I added the soda and blended on and off until medium trace

I added 10 ml of Tea Tree oil and blended until mixed

Then I poured the mixture into two beer can moulds and covered in cling film

Does anyone know why the center of the soap is dark?

Are other people's cold process soaps still tacky after 2 days?

Thanks

Constructive comments welcome.

Last edited: